Ceramic tile is the most common form of surface on counters today. This is due to the extreme variety

of color, texture, price, pattern choices and availability.

Ceramic tile, along with its sister product porcelain tile, is an excellent choice for kitchens, baths

and surrounds. Ceramic pieces such as liners, dots, inserts and decos can enhance designs on their own

or in conjunction with each other form picture frames, intricate patterns, stacked liner designs or

unique edge treatments. Often metallic decos, glass, stone or resin pieces are added to ceramic to

attain beautiful designs.

Generally ceramic wall tile comes in 4 and 6-inch square sizes. Diamond, hexagon, rectangular and other

shapes are available depending on the tile line. Surface trim such as quarter round, bullnosing and v-cap

are commonly used to finish the edges of a ceramic tile installation. These trim pieces are meant to blend

with the field material and rarely match exactly.

Certain ceramic tiles are suited only for bathroom use based on their construction. Ceramic is easily cleaned

and non-porous. Ceramic tiles must be installed with grout joints and all grout should be sealed prior to use.

Grout joints also tend to soil in heavily used areas such as bath counters and kitchens.

Ceramic tile construction is fully explored in the

flooring section of this website.

Natural stone is a product that has unmatched physical beauty. The natural characteristics of stone are exalted

in the flooring section of the “material selection” link on this website. On counters natural stone comes in

two forms, tile and slab.

Natural stone slab material is found and quarried all over the world. A multitude of unique color, pattern and

density distinguish this material from any other. The three most common types of slab material are granite, marble

and travertine. Each of these materials has individual characteristics that will be explored later but their common

denominator is uninterrupted beauty. The natural features of these materials are not interrupted by grout joints,

allowing the full beauty of the material to shine through and facilitating easy maintenance. Slab materials may have

a slightly higher initial cost but will prove their value over time due to their durability, low maintenance cost and

enduring great looks.

Slab material is quarried in large blocks. These blocks are then sliced most often into ¾” slabs. Filler is added to

one face of the slab to fill any voids or small fissures and then a process of honing or polishing takes place. Honing

is the sanding of the material to a smooth and matte finish. Polishing occurs on other materials delivering a high shine.

Generally the harder the material the shinier it can be polished. Diamonds are a good example of that statement. The

slabs are crated in bundles and sent to slab yards where you can go to approve the actual slab used in your home. Each

slab is different and will demonstrate veining and other significant features.

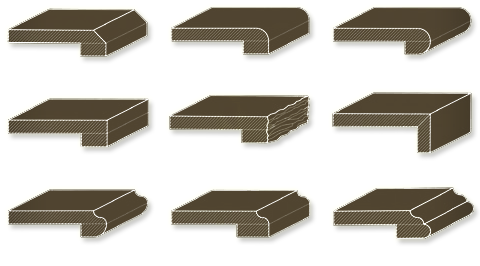

During the fabrication of your slab counters a variety of edges can be applied to the leading edge of your countertop.

Generally you need to consider aesthetics and comfort when evaluating each edge. Price is determined on these edges

according to how intricate the stone is carved. Some common edges are illustrated below.

Granite is the strongest and most dense stone material used in construction. It is recommended for any application

including fireplace surrounds, kitchen counters and splashes and bathroom counters and splashes. Granite ranges in color

from Jet-black to vivid reds to vibrant blues. Granite can be a single solid color or found to display wonderful waves

of color. Granite is generally priced according to its rarity, availability and fabrication difficulty.

Granite is resistant to heat, not affected by most food acids, tea, coffee, alcohol or wine. Granite also resists most

bacterial growth. Due to its relative hardness it is much harder to scratch than marble or travertine.

Granite slab material averages about 60” in width and 108” in length. If the counters you are covering exceed these

dimensions you will have a seam. Granite seams are affixed using colored epoxy that best blends with the natural stone color.

Marble is an excellent material for bathroom countertops. While it is not hard enough and too porous for kitchens the

softer palate of colors and veining make it a great selection for these more private areas. Many spas frequently use

marble as the main material in their design specifications. Marble color ranges from rich dark browns to nearly pure

white. Marble has more veining than granite and is cut into smaller slabs at the quarries to insure it arrives in one

piece to the slab yards. Marble is an excellent choice for hearths and surrounds.

Many food acids, wine, coffee and other common foods and drinks, adversely affect granite. Marble is easier to fabricate

and found more readily in the world, which reduces the cost of this material.

Travertine is the softest of the three slab materials. It will have more fill and exhibit a more matte finish when compared

to marble and granite. It has a very popular and unique look offering a relaxed yet refined counter treatment. Travertine’s

cloud-like face characteristics are utilized in baths and offer a wide variety of colors.

Natural stone tile has been used as counter material in a variety of forms for hundreds of years. Stone on counters can be

made of slate, travertine, marble, granite, limestone, onyx and even more materials that are found in nature. These stone

materials can come in an array of sizes and finishes. The common sizes start at ½ “ mosaic sheets to 1, 2, 3, 4, 6, 8, 12, 16

and 18 inch squares. In addition to square shapes many patterns are available featuring stone material today. Additionally

technology exists to shape many stones into three- dimensional pieces such as pencil rails, chair rails and decos.

The finishes depending on the material can be polished, honed, tumbled or even split faced. Each material may or may not

have the characteristics to be manipulated into these finishes and sizes.

The way in which a stone is finished greatly affects its appearance and use. Below are a few common terms associated with

stone finishing.

This type of finishing results in a matte finish on the tile face. Honing will temper the color and also leave the face smooth.

A polished finish leaves the material shiny and glasslike. This finish is most often used in contemporary designs. This

finish is slippery when wet and tends to show water marks in darker materials.

Tumbling leaves both the face and edge with a rustic worn appearance. This finish is used a lot in Spanish,

Mediterranean and other design settings where a relaxed or casual style is desired. Additionally, tumbling can

camouflage many soil or wear issues.

This is a finish that is achieved buy splitting the material apart as opposed to cutting it. This leaves the material

very rustic and rough. Slate is the most common product associated with this finish.

This is a treatment that chips away material leaving a very rustic edge. This treatment is very dramatic but not very

comfortable, it is usually used on vertical surfaces.

This edge is similar to the edge of a beveled mirror. This edge is soft afoot and adds depth to the installation

revealing a terrific texture to any surface it adorns. Saltillo tiles are an illustration of this edge.